Microwave Drying

Flowers and High Terpene Plant Materials

EnWave’s low-temperature process quickly and uniformly dries organic material to the precise moisture needed for combustible or extractable flower.

High Capacity Processing

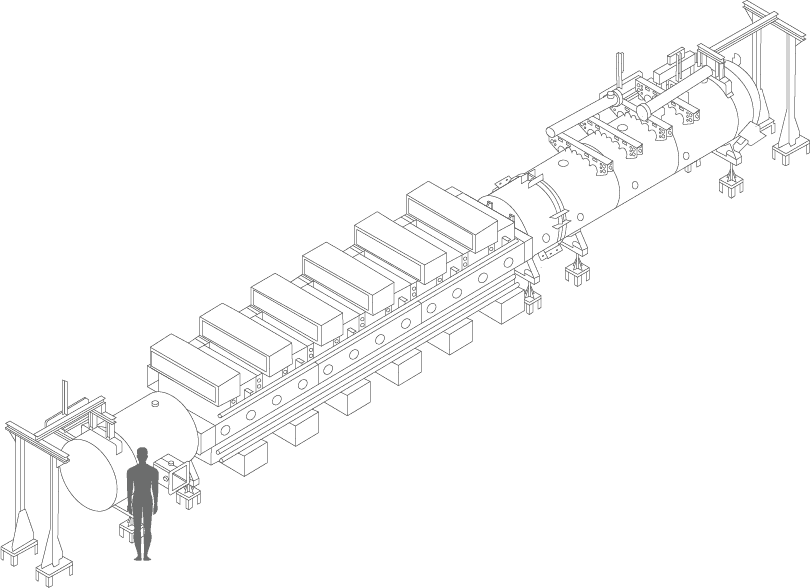

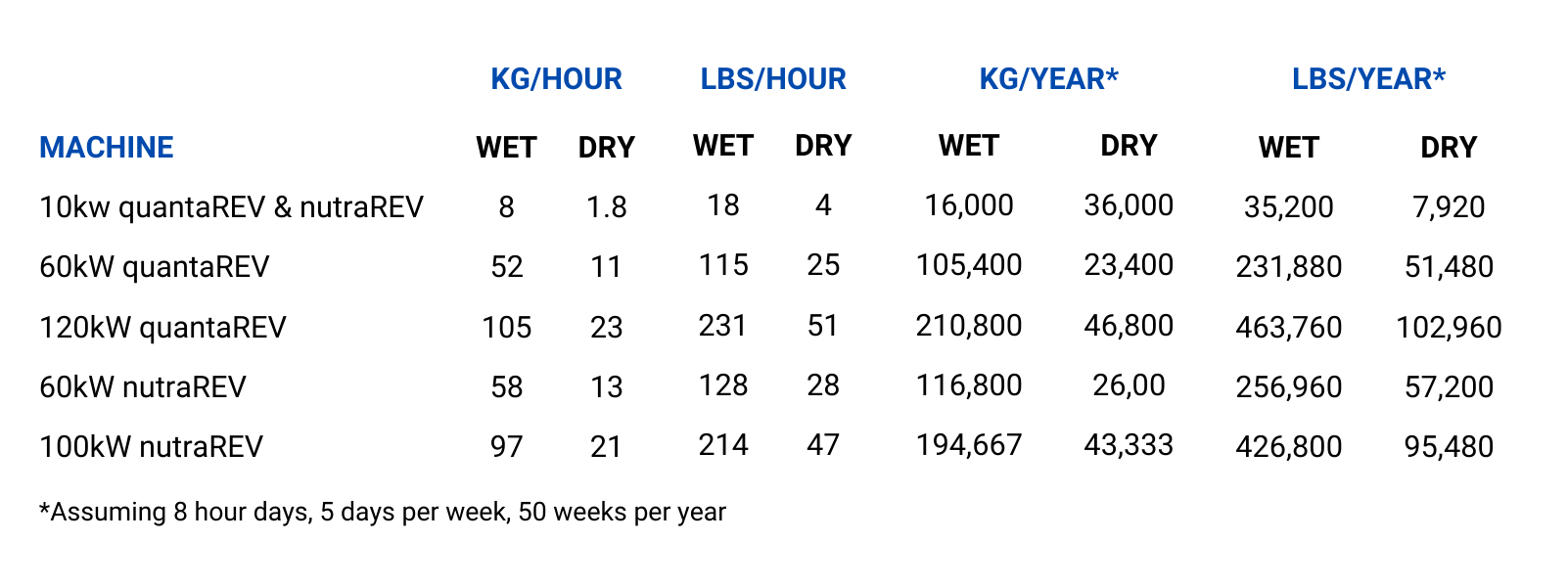

A single 120 kW quantaREV® system can dry about 840 kg (about 1850 lbs) of wet flower in a single 8-hour day, producing about 190 kg (about 420 lbs) of dry flower per shift.

Operating just two shifts per day, 5 days per week, a single machine can dry about 420,000 kg (about 925,000 lbs) of wet flower yielding about 95,000 kg (about 209,000 lbs) of dry flower per year.

Benefits

High Speed Processing

New Product Opportunities

Scalability

Reduced Energy Usage

Continuous Processing

Flexible Moisture Content

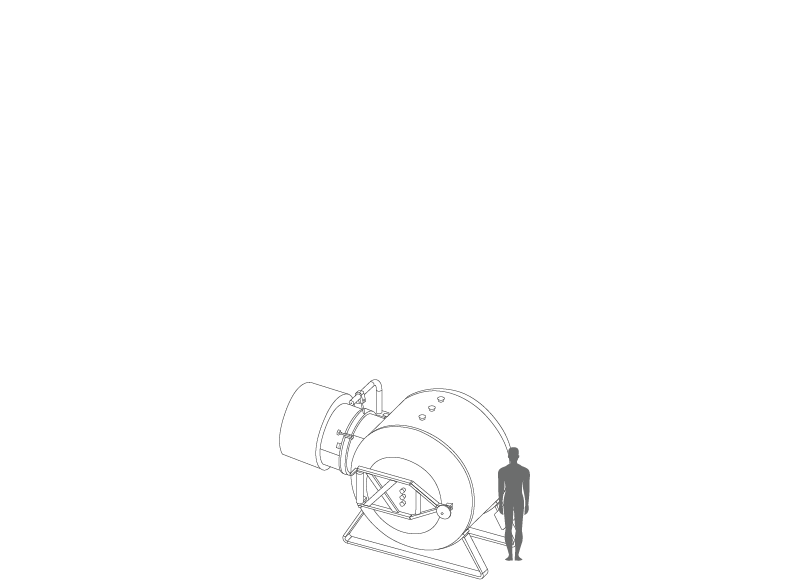

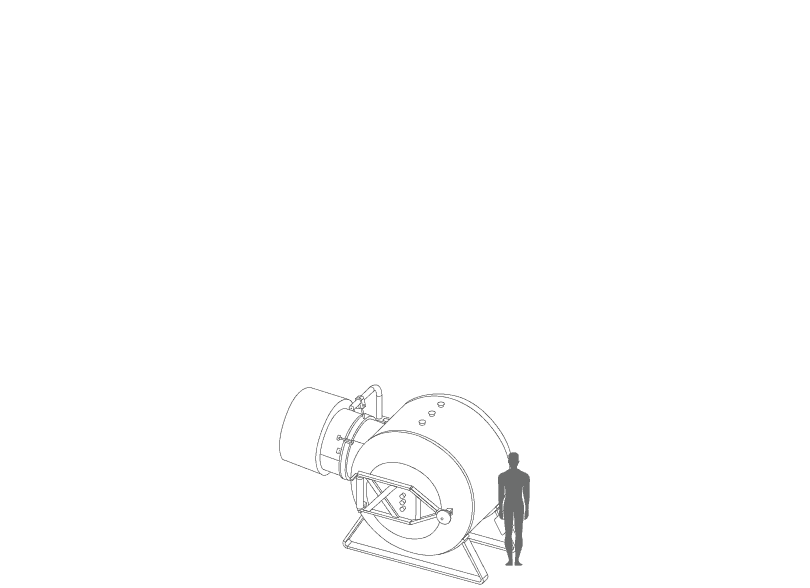

NutraRev

The product load tumbles in rotating drums, moving through the vacuum microwave chamber, as the microwave energy is used to homogeneously dehydrate the product load to a desired residual moisture content.

10KW MACHINE

Suitable For:

Market trials, product innovation & testing, small-scale producers

Microwave Power: 10 kW

Frequency: 2450 MHz

Vacuum: 12-300 Torr

Footprint: 2.4 x 1.8 x 3.1 m (LWH)

Capacity: 9.1 kg of water removal per hour

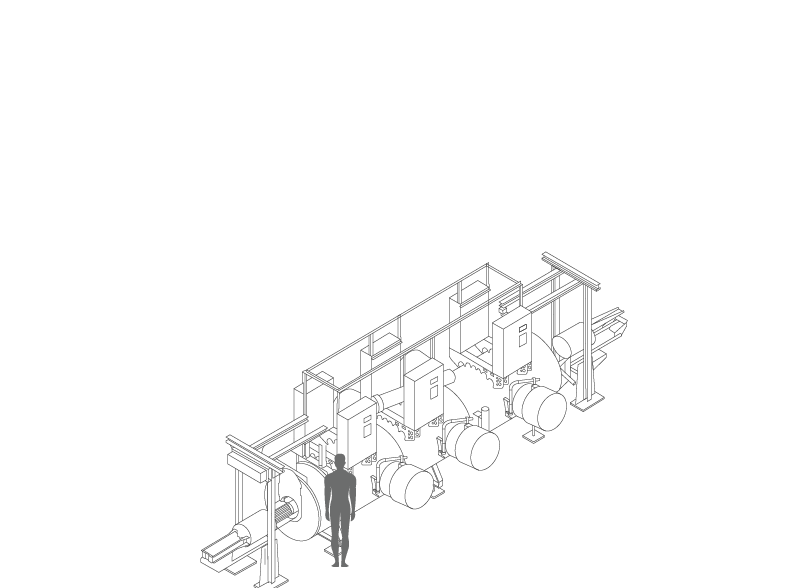

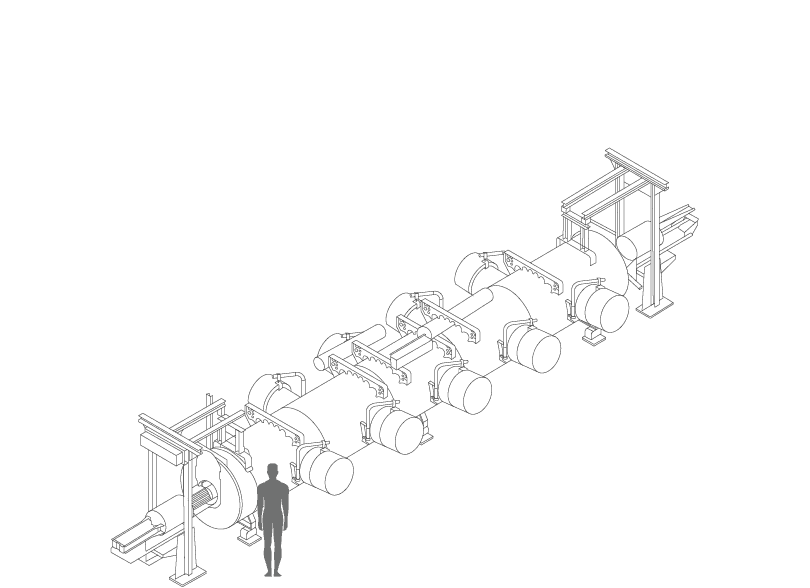

Quantarev

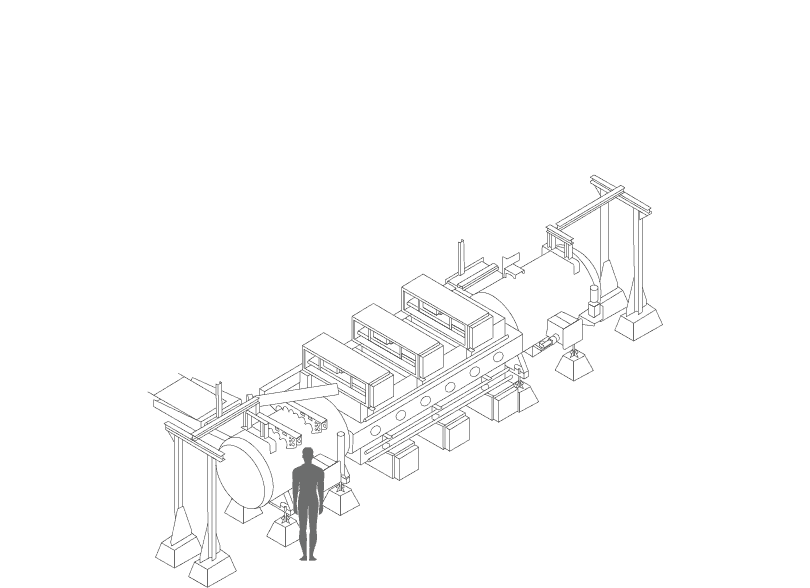

The quantaREV® process begins by placing product loads into microwave transparent trays outside the dryer under ambient pressure.

Those trays are then fed into the vacuum chamber via a belt, through a double sluice entry. Within the dryer the trays are transported continuously one behind the other.

The product is discharged via a final horizontal sluice. The dried product load is then removed from the trays outside the machinery.

10KW MACHINE

Suitable For:

Market trials, product innovation & testing, small-scale producers

Microwave Power: 10 kW

Frequency: 2450 MHz

Vacuum: 12-300 Torr

Footprint: 2.4 x 1.8 x 3.1 m (LWH)

Capacity: 9.1 kg of water removal per hour