Decarboxylation

Decarb Oven CDO-5-CS

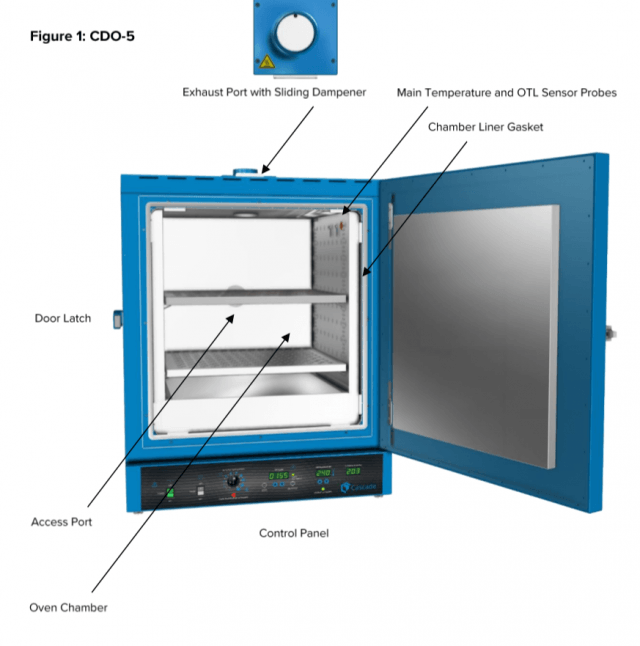

Cascade’s CDO-5 is purpose-built for bench-top, R&D drying and decarboxylation of material with additional features.

This powerful bench-top forced air laboratory oven uses heated air to remove unwanted compounds from products that are not temperature sensitive. Our ovens feature horizontal airflow that enables more consistent distribution of air. They are designed to have uniform temperatures and airflow across the shelf space from right to left.

The CDO-5 includes a built-in humidity sensor and fine micron mesh bags for drying or decarboxylating powders or ground material.

Additional Features

- Built-in Humidity Sensor assists in monitoring dryness

- Stay in place sliding extension shelves, stainless steel – 2 each

- NRTL Certification

- 2 each FDA temp rated fine micron mesh bags for ground material

Dry / Decarb Oven CDO-28

Cascade’s CDO-28 is purpose-built for large-scale, industrial decarboxylation of material with additional features

This powerful, large capacity forced air laboratory oven uses heated air to remove unwanted compounds from products that are not temperature sensitive. Our ovens feature horizontal airflow that enables more consistent distribution of air. They are designed to have uniform temperatures and airflow across the shelf space from right to left.

The CDO-28 includes a built-in humidity sensor and fine micron mesh bags for drying or decarboxylating powders or ground material.

Additional Features

- Built-in Humidity Sensor assists in dryness targets

- Stay in place sliding extension shelves

- NRTL Certification

- Temp rated fine micron mesh bags for ground material

Chemistry Pumping Unit - PC 3004 VARIO

VARIO® pumps and pumping units provide precise vacuum control by adaptation of the diaphragm pump´s motor speed. They feature fully automatic evaporation control on the push of a button. The basic pump is the three-stage MD 4C NT VARIO chemistry diaphragm pump which meets high vacuum requirements for most high boiling solvents. The PC 3004 VARIO offers a well proven choice for evaporation of large amounts of solvents. The separator at the inlet, made of glass with protective coating, retains particles and liquid droplets. The waste vapor condenser at the outlet enables near-100-percent solvent recovery, efficient recycling and active environmental protection. The on-demand motor speed control results in unsurpassed lifetimes of service parts, such as diaphragms.

Performance Features

- automatic adaptation of the vacuum level throughout the process for high process reliability and unattended operation

- short process times due to high pumping speed and zero-fluctuation (hysteresis-free) vacuum control

- easily operated CVC 3000 vacuum controller with clear text menus, with integrated venting valve

- extraordinary diaphragm life, therefore minimum operational and servicing costs

- PC 3004 VARIO: excellent environmental friendliness due to efficient solvent recovery