Freeze Drying

Freeze-drying systems for your high-quality product manufacturing

Scitek and its partners support you all the way from the first laboratory trials through the demanding task of process development to the high-quality production of your valuable products.

With many years of experience and expertise in the design and manufacture of production systems, Christ is able to provide application-specific solutions fully tailored to the needs of our customers.

Typically manufacture production systems with ice condenser capacities from 20 kg to 500 kg or more. Either single-chamber or double-chamber systems can be used, depending on the characteristics of the product.

They cover the full spectrum of typical applications with three basic system types.

Drying bulk materials (single-chamber systems)

Download Brochure

Supplier Website

Christ Epsilon single-chamber systems are always a good choice when the primary consideration is high drying performance with low capital expenditure and low energy costs. They also ensure reliable and economical operation year after year. With large shelf area and adjustable shelf spacing, they are general-purpose systems with high ice condenser capacity.

Advantages of Christ single-chamber systems:

Applications:

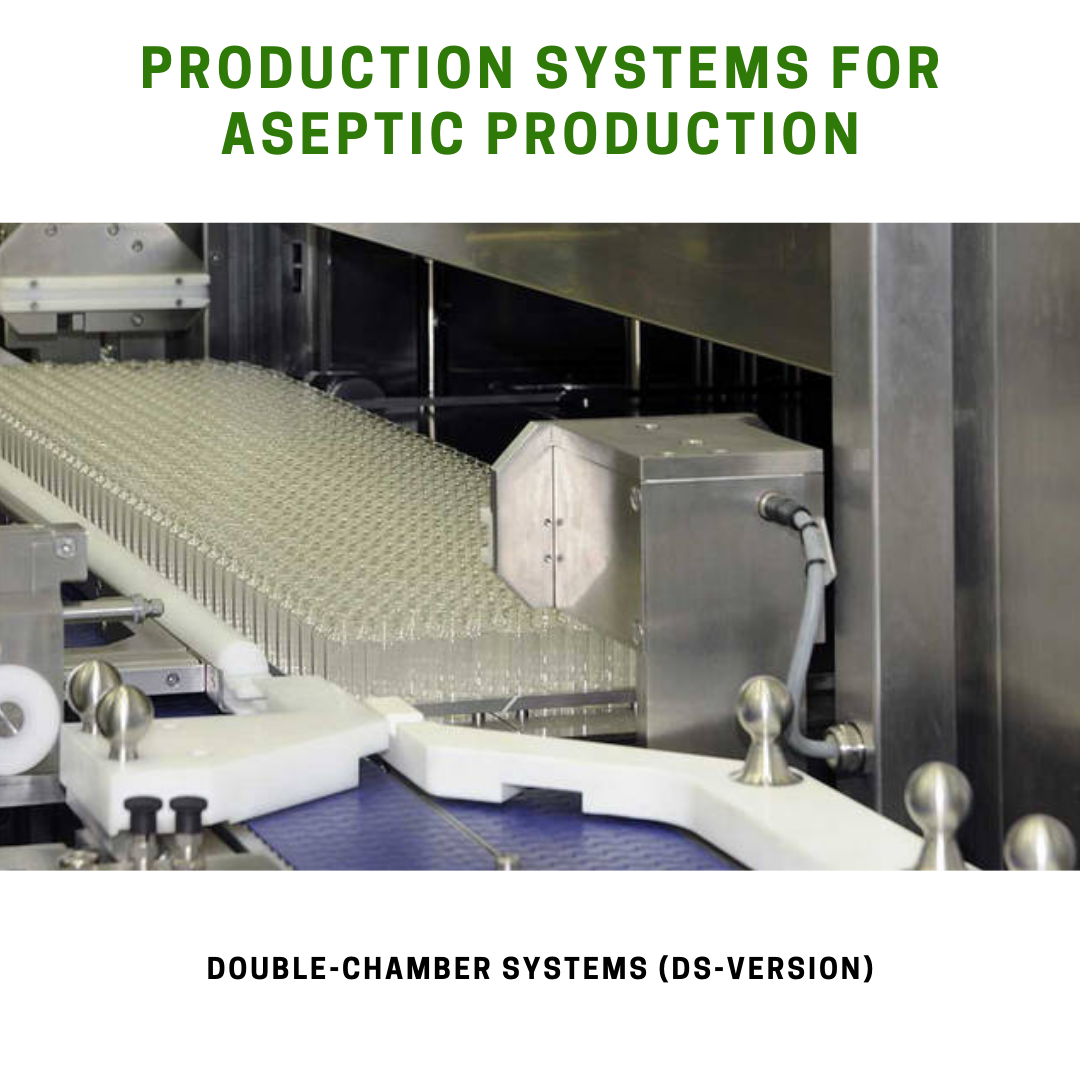

Production systems for aseptic production of active ingredients (double-chamber systems)

Custom system projects

Long before your system dries the first batch of your valuable product, our qualified project management, engineering and service team provides the necessary advice and support for everything from system design, seamless quality control during production, on-time installation, commissioning and qualification, and ensuring the reproducible and trouble-free long-term operation of your freeze drying system. If technical problems arise, you can count on fast response from our Service team 24/7, 365 days a year.

Structural or component positioning modifications for adaptation to space constraints are possible, as well as alternative arrangements for vacuum, cooling and control. We offer a broad selection of solutions at various levels for secure freeze dryer loading and unloading solutions, which is naturally a significant issue for users. They range from configurations with attached isolators to semi-automatic loading carts and fully automatic loading and unloading systems. The latter systems can be implemented conventionally using conveyor belts or transfer carts, or innovatively using cleanroom robots for unparalleled precision and reliability. Mature solutions are assured by our ‘best partner’ approach, which means working with leading specialists in their fields. Christ normally assumes the role of lead supplier to minimise the number of contact persons.

All systems and equipment fulfil the most stringent requirements with regard to the materials used and functional safety, and they are extensible and upgradable for future applications. Advanced automation concepts simplify operation for users and ensure fully reproducible drying processes. Our experts are active in major associations and working groups, including ISPE and the German PAT group, and are therefore familiar with stringent regulatory requirements, particularly with regard to the pharmaceutical and biotech industries.

We work with users to devise system and loading concepts for an extremely wide range of tasks and process requirements and implement them in manufacturable designs.

The double-chamber design developed by Christ places the ice condenser directly below the drying chamber. There is a wide choice of sizes, with ice condenser capacities from 12 kg to more than 500 kg. The shelf area ranges from 1 m² (specifically for process optimisation) to over 40 m², depending on the system type.

Our Epsilon DS freeze drying systems feature:

Typical applications

Laboratory freeze-dryer

Laboratory freeze-dryer are capable of handling production capacities from 2.5 kg to 24 kg per drying cycle.

The version with LSCbasic control is particularly suited to standard applications in round-bottomed or similar flasks and small quantities in product trays and other containers. For advanced applications requiring more process control and/or temperature-controlled shelves for the product, we recommend the LSCplus range.

Almost all models are available with ice condenser temperatures of approx. -55 °C (main application: aqueous solutions) and -85 °C and -105 °C (for products with low freezing points, e.g. solvents).

Models

Alpha 3-4 LSCbasic

Universal solvent packet – flasks and storage surface:

Alpha 3-4 LSCbasic freeze dryer with internal condenser, made entirely of stainless steel (316L)

Condenser capacity: 4 kg

Condenser temperature: -105 °C

- Optimized ice condenser

- Capacitive vacuum measurement probe

- Drying chamber made of mineral glass with transparent splinter shield foil

- Flow tube for optimal ice distribution

- Base plate made of stainless steel

- 3 storage spaces, diameter 265 mm, unheated

- 12 chemical-resistant valves for flaskss

- Benchtop Freeze Dryer