Ethanol Extraction

Mach Centrifuge Extraction Units

Mach Technologies stand alone centrifuge extraction equipment was designed for specialized botanical extraction using ethanol. Our system uses state of the art controls, and is 100% manufactured in the U.S.A. in our vertically integrated facility in Michigan.

- Up to 98% botanical compound removal

- Up to 97% ethanol removal from biomass

- Single-operator state of the art controls

CES-300

Model: CES-300

Capacity: 8-13 lbs per batch, up to 300 lbs per shift

Batch Cycle Time: Typical 10-15 minutes

Footprint: 26" L x 36" W x 77" H

*Footprint for stand alone centrifuge

CES-1000

Model: CES-1000

Capacity: 40-55 lbs per batch, up to 1000 lbs per shift

Batch Cycle Time: Typical 15-20 minutes

Footprint: 48” L x 38” W x 78” H

*Footprint for stand alone centrifuge

CES-600

Model: CES-600

Capacity: 25-30 LBS per batch, up to 650 LBS per shift

Batch Cycle Time: Typical 15-20 minutes

Footprint: 45.5" W 43" D x 68.75" H

*Footprint for stand alone centrifuge

X10 MSE - Extraction System

The X10 MSE (multi-solvent extractor) is the company’s flagship extraction system. Utilizing ethanol solvents, the X10 processes more than 10 lbs of material per run with an average 55 minute recovery time* making it ideal for mid-level commercial production and craft applications. With patent pending jacketed vessels, the X10 comes equipped with on-demand heating and chilling, providing the system with maximum control and ease of operation.

Ethanol Specifications

Temperature Control Options

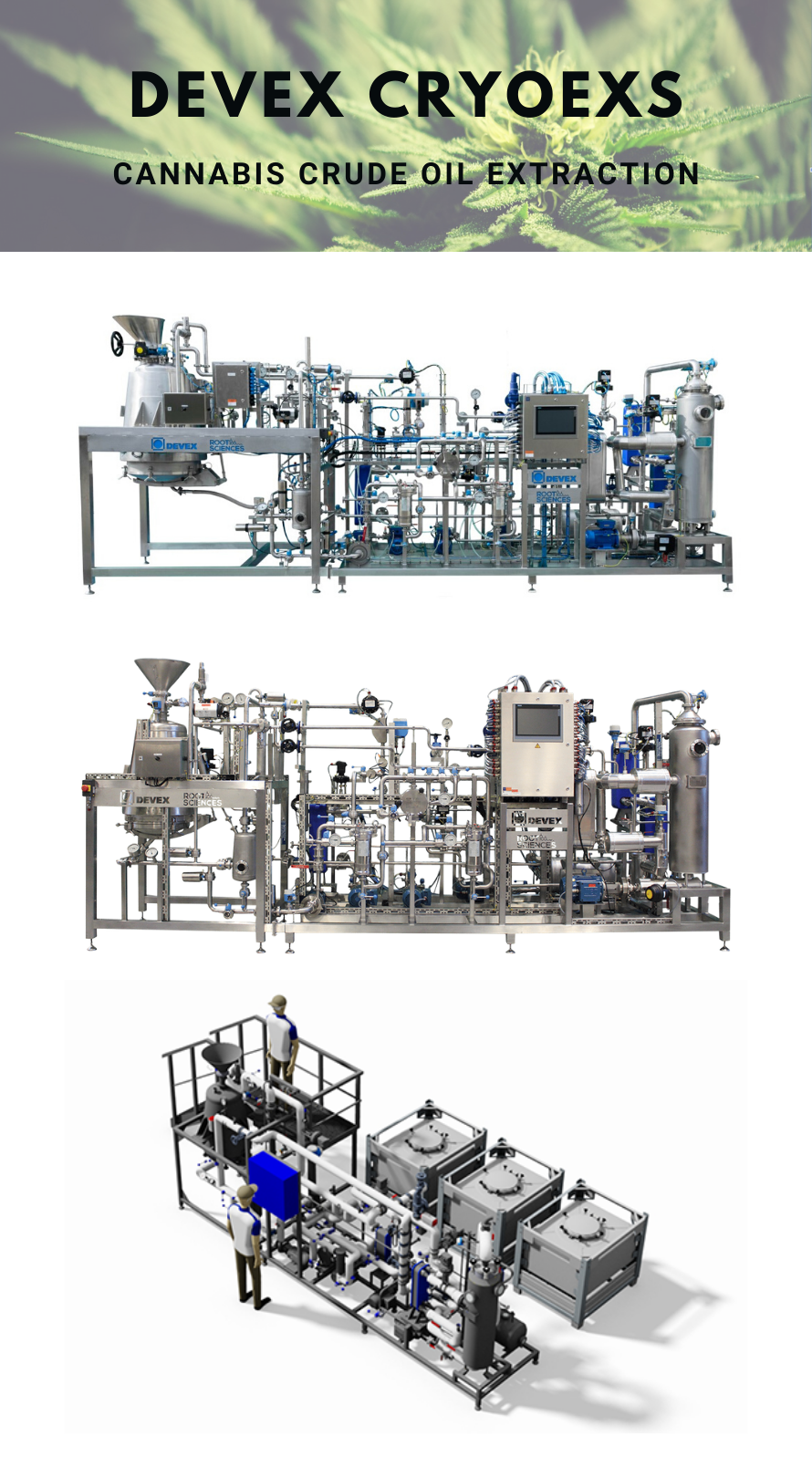

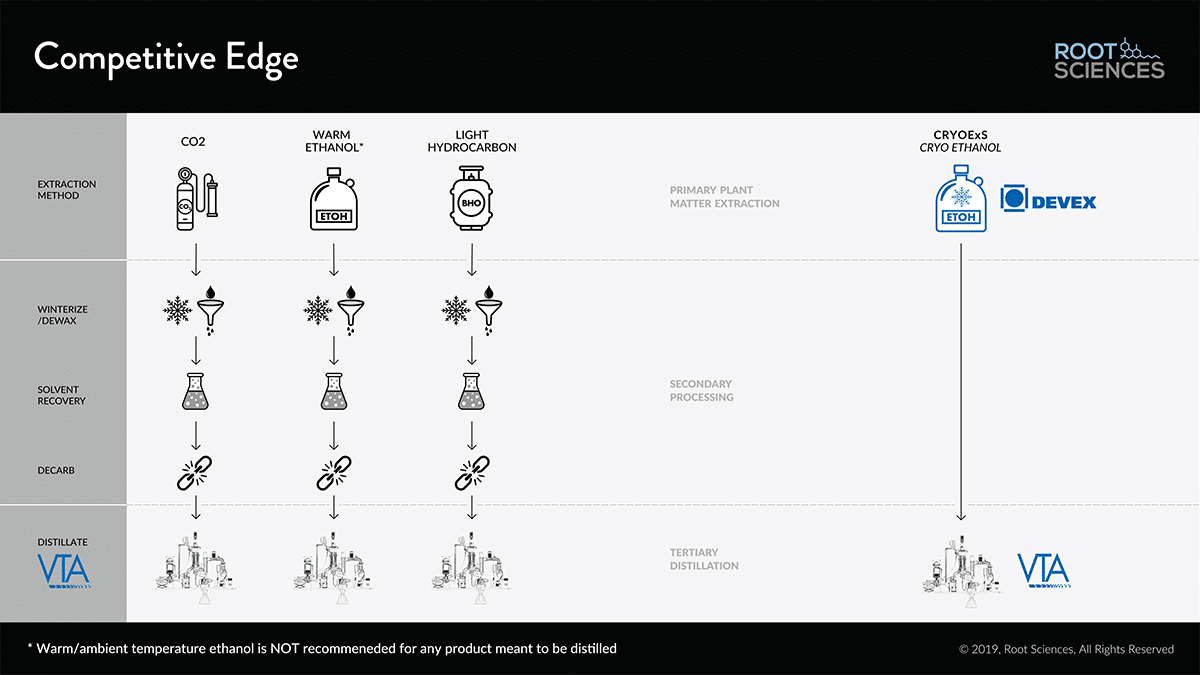

Devex CryoEXS - Crude Oil Extraction

All-in-one Cryo-Extraction, Solvent Recovery and Decarboxylation system. Features: Low residual solvent left in spent biomass by means of steam stripping; Extraction temperature: sub-zero, no need to de-wax.

DEVEX Design (Connect-plug-product) : The DEVEX Cryo Ethanol Extraction System is mounted on two stainless steel skids. The DEVEX Cryo Ethanol Extraction System is supplied completely piped, cabled and can be used directly after interconnection of the two skids and connection to the utilities.

DEVEX CryoEXS 400

The DEVEX Cryo Ethanol Extraction System provides the following processes;

Explosion Protection

Due to the use of ethanol for solvent the equipment is designed to match with hazardous environment conditions Ethanol IIB T3, inside zone 1 / outside zone 2 (ATEX II 2G / ATEX II 3G). For the North American market the system is designed to match the conditions NEMA Class I Division 2 (CID2).

Material

Parts in contact with product or solvent: AISI 316, 316 L, 316 Ti

Technical Data - CryoEXS400

Ethanol Recovery

Extraction

Parts in contact with product or solvent: AISI 316, 316 L, 316 Ti